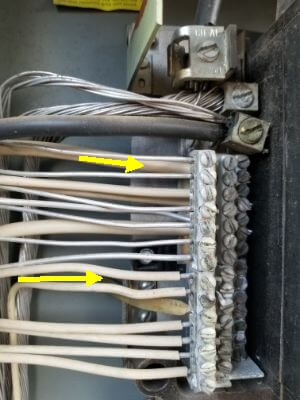

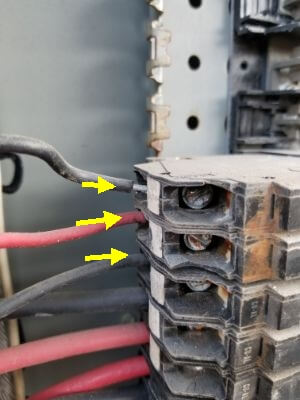

Single-stranded aluminum wiring, also known as solid aluminum wiring, was a type of wiring that was used in homes during the same period as multi-stranded aluminum wiring. Unlike multi-stranded aluminum wiring, which consists of several smaller wires wrapped together, single-stranded aluminum wiring consists of a single wire. This type of wiring was used primarily as branch circuit wiring, which means it connected individual outlets, switches, and fixtures to the larger electrical system. While single-stranded aluminum wiring was cheaper and lighter than copper wiring, it was also found to be less stable, making it more prone to overheating and potential fire hazards. Homeowners and buyers should be aware of the potential hazards associated with single-stranded aluminum wiring and should consult with a licensed electrician or inspector to assess the electrical system's safety in any home built during the period when aluminum wiring was used. Era When Single-Stran